By:

- Katherine Connor

Published Date

By:

- Katherine Connor

Share This:

From Sea to Sky, Students Develop Tools for Improved Environmental Monitoring

Undergraduate mechanical engineering students at UC San Diego developed tools to improve our ability to source environmental data from hard to access places, like deep in the ocean, or high in the sky. For their Jacobs School of Engineering capstone senior design projects, two teams took on the challenges of designing a drone system to capture air samples around the world, and a deep-sea data buoy system to collect underwater environmental data, respectively.

The drone team, sponsored by researchers at the Scripps Institution of Oceanography in the Keeling and Weiss labs, was tasked with transforming a drone into a portable air and atmospheric data collector. Researchers in these labs use data from air samples to feed the famous Keeling Curve, a daily record of global atmospheric carbon dioxide concentration that is critical to our understanding of climate change. The Weiss lab also uses these samples to better track trace gases and other environmental data points gathered in the air. To get representative samples not affected by local contamination, the researchers currently rely on tall, permanent towers limited to several set locations where such structures are feasible, that collect samples above the threshold of local contamination.

A team of four mechanical engineering undergraduate students developed the components necessary to turn an off-the-shelf drone into a portable air sample collector, allowing well-mixed air samples to be retrieved from locations without an existing collection tower. This solution is both less expensive and allows more precise control of the sampling location when compared to the logistics of building a permanent tower, and could be used in tandem with existing collection towers to source samples from more locations.

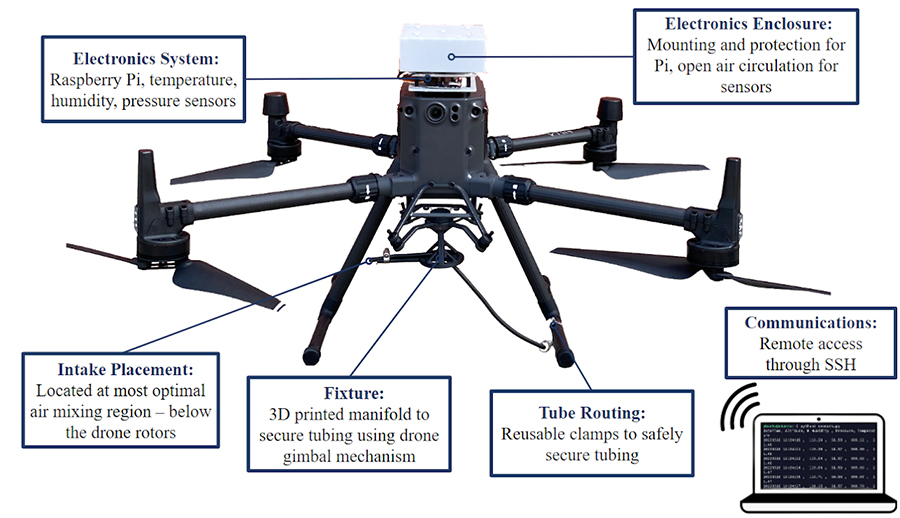

The final design, including the added sensor mount, with all attachment floors and sidewalls. The tubing attachment is seen under the drone.

To build a working collection drone, the students first decided where the best spot to affix the tubing that would collect the air would be; they targeted a location under the rotors where the high downdraft would minimize heating of the inlet, a design inspired by the "aspirated" inlets used in the Keeling lab. They then designed a 3D-printed mount to affix one end of the 100-foot-long plastic tubing that funnels the air samples back to the ground. The plastic tubing material, Kynar™, was chosen for being a flexible tubing medium that itself doesn’t contaminate the samples, while the 100 feet length was chosen as a first approximation of the height needed to go above the local contamination: both of these assumptions will be tested in future experiments. The plastic tubing is connected on the other end to a flask and pump on the ground where the samples are stored. They also designed a mounted shelf system that allows other sensors—like temperature, pressure, humidity and altitude, for example—to be attached on top of the drone, and transmit their data to the ground station through a Raspberry Pi.

The students conducted extensive testing with the drone and their collection system in the UC San Diego Aerodrome, a netted outdoor flight space for drone research, and provided documentation and training on how to use the system to their sponsors.

“I think we learned a lot in terms of teamwork among ourselves, because there are so many moving components with electronics and the fixture and drone flying,” said Rachel Luu, one member of the team. “When it all comes together at the end that's really exciting. We all really enjoyed the research aspect of this project and how it can help with global warming tracking and the environmental issues we’re facing.”

Team members: Rhianne Purificacion, Colleen Wolfe, Rachel Luu and Tristan Kinney from Scripps Institution of Oceanography.

Learn more about this project on the Keeling Curve website.

Sourcing undersea data

On the other end of the spectrum, another team of students was tasked by their sponsor, the Naval Information Warfare Center Pacific, with creating a deep sea data collection system to gather information on the presence of dichlorodiphenyltrichloroethane—DDT, a powerful insecticide—and other undersea pollutants.

Instead of having to deploy individual buoys with sensors inside on a routine basis, their sponsor wanted one large system that would contain multiple buoys with sensors, reducing the down time required to collect the buoy, gather the information, and then redeploy it.

The students designed a large, pentagonal device made up of six smaller buoys, each with its own sensors and GPS tracker safely inside. The goal is to send the whole device down into the deep sea, and have each buoy be able to surface at a set period of time—for example, one buoy might surface every other month, meaning only one deployment per year is necessary. The GPS tracker in each pod makes retrieving the pods and data when they surface much simpler.

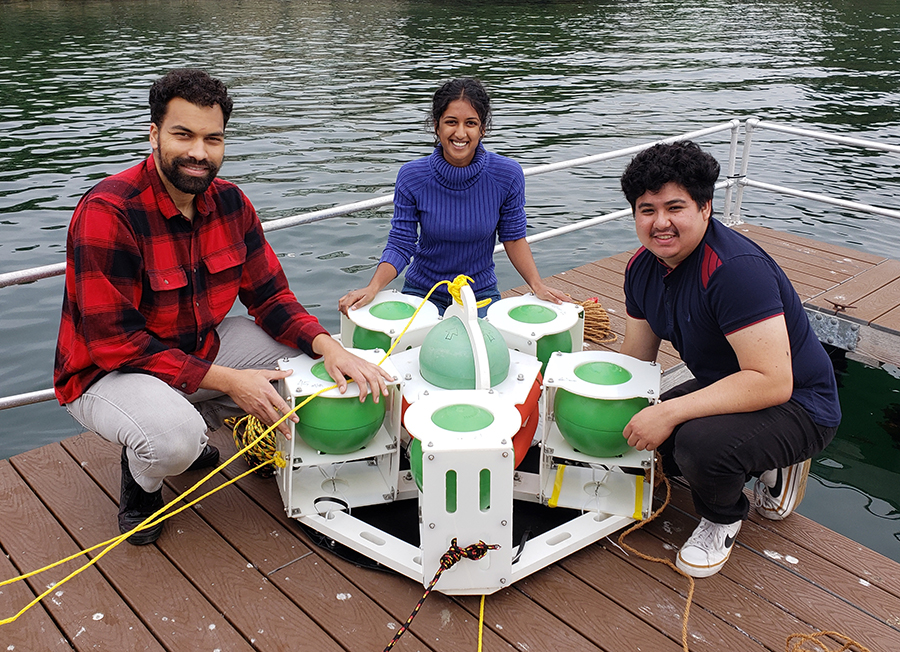

Students S Grimes, Ananya Thridandam and Brandon Orozco test a prototype of their device.

To create their prototype, the students had to figure out everything from the ideal size and shape of the system, to how to ensure each pod is fully waterproofed. They calculated the proper displacement required for each pod to surface out of the ocean enough for satellites to be able to track the GPS unit; found and tested a passive chemical reaction release tool that could be used for the delayed-time release of each pod; and ensured the main device was buoyant enough to stay at the prescribed ocean depth until it’s time to resurface, even while the smaller pods surface individually.

The students learned a lot during the course of the 10-week project.

“I mostly focused on designing the buoy housing pods and I believe it was like seven iterations that I went through,” said Brandon Orozco. “So what I learned is there's always something that you can improve, with every meeting or while talking to the sponsor there's always something that you can focus on in the next iteration.”

For S Grimes, it was being able to see a project through from start to finish.

“I really liked the idea of drawing something up and thinking about it and being able to cut it up and then see it put it together and build and test it; going through that whole process was really great. It’s really cool to feel like we’re taking all the theory that we've learned and applying it to an impactful idea.”

“I think one of the big things is learning to rely on my team,” said Ananya Thridandam. After learning early on that the team had made a mistake in their design calculation, panic began to set in. “I was thinking we just spent seven straight hours on this, and I was overwhelmed and thinking I don’t know how we’re going to make it work. The next day someone else was like okay we figured out an alternative. I learned to rely more on the team; you have to pass the ball between your teammates in order to accomplish something like this.”

Team members: Ananya Thridandam, S Grimes, Brandon Orozco and Klever Pirir-Jimenez.

These teams of students were two of more than 30 teams this year that spent 10 weeks creating solutions to real world problems put forth by members of the community and local companies. It’s part of the capstone senior design course that all mechanical and aerospace engineering students take. The goal is to provide students an opportunity to put all they’ve learned into practice, working within real world constraints like budgets and timelines. For more information on the senior design course or sponsoring a project visit the project's website.

Share This:

You May Also Like

Stay in the Know

Keep up with all the latest from UC San Diego. Subscribe to the newsletter today.