Engineering Students Aim to Take 3D-Printed AUV to the Arctic

Media contact:

Published Date

Article Content

By: Kiran Kumar

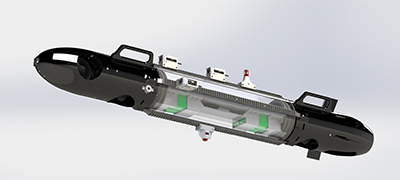

Undergraduate engineering students in the Yonder Deep student organization have found a way to sharpen their marine robotics skills while working toward solutions to the climate crisis. The organization, now in its fifth year, aims to design and 3D print a low-cost, modular, and fully autonomous underwater vehicle (AUV), that will enable researchers to affordably collect oceanographic and climate data.

Yonder Deep’s ultimate goal is to design a torpedo-like AUV that will house a whole suite of sensors– temperature, pressure, hydrophones, – versatile enough to withstand the frigid waters of the Arctic as well as the churning coastal waters of Southern California.

One of the first missions that the student team is working to help quantify is glacier melt and subsequent sea level rise. Arctic research instruments that utilize advanced sensors to measure the rate of glaciers melting already exist, but getting these within close proximity to glacier terminuses can be challenging due to the dangerous nature of glacier research. AUVs are a great solution to this problem, but they can be expensive, with entry-level AUVs often costing upwards of $300,000. The Yonder Deep team identified this massive barrier of entry into the field of oceanographic research and sought to address it. Over the past five years, under the mentorship of physical oceanographer Grant Deane, a researcher in the Marine Physical Lab at Scripps Institution of Oceanography at UC San Diego, the team has been developing a low-cost AUV using 3D printing.

Deane’s research is in the field of hydroacoustics. The AUV that the students are developing uses hydrophones to measure the rate of ice melting. As the ice melts, air is trapped inside the ice as bubbles escape, making a crackling noise. By monitoring the rate of these crackling noises, you can identify how fast the ice is melting. Developing the AUV for data collection is where Yonder Deep’s AUV comes into play.

Yonder Deep leaders and mechanical engineering students Daniel Ju and Satchel Birch said designing their AUV to withstand this glacial environment presents some challenges, one of which is operating in the extremely cold conditions of the Arctic. The team had to consider how the porous material’s water absorption would influence the object's weight and buoyancy. The team also had to study the durability, behavior, and geometry of the 3D-printed material and determine whether it would withstand these severe conditions.

Apart from the goal of creating an affordable and versatile research AUV, the team has broader aims to apply their engineering skills for good.

“As engineers, it’s also important to think how we can use our unique skills to help tackle a problem that is usually approached as a social issue,” said Daniel Ju, a mechanical engineering student, former president, and now a technical advisor and mechanical architect at Yonder Deep. “Climate change is an incredibly pressing global issue, and this project provides students with an opportunity to leave a large impact on the world while simultaneously developing important engineering skills.”

“Being able to study climate change, but also work to increase access to quality oceanographic research for the future is what I think makes our mission so exciting” says Satchel Birch, a mechanical engineering student and current president of Yonder Deep. “On top of that, doing this as a team of only undergrads is a great opportunity to learn and teach together. One of my best memories was conducting these buoyancy calculations and seeing them work as a team during salt-water pool tests at Scripps.”

The nature of Yonder Deep’s work is also unprecedented.

“3D printing is normally used for prototyping, but our unique designs and processes enable the use of more additive manufacturing, which are the main reasons why Yonder Deep’s strategy is so versatile and affordable,” said Ju.

Instead of using conventional methods of manufacturing, Ju says that their decision to 3D print is “what makes this project so fun because no one has done this type of work at this scale before.”

The Yonder Deep team is currently on their 4th full-scale prototype, and they anticipate that their current AUV will be ready for intensive testing by the end of summer 2023. If the team can successfully meet their testing goals by that point, Deane has plans to use their AUV for his upcoming research trip to the Arctic.

“The Yonder Deep team is pushing the frontier of low-cost, high-value marine platforms for research in high-risk polar regions,” said Deane. “This kind of work is critical to understanding sea level rise and developing systems for monitoring the Greenland ice sheet. It’s exciting to be working with this dynamic, motivated, and talented team of engineers to achieve these goals.”

Yonder Deep is one of the student organizations working out of the new Qualcomm Student Space in the recently opened Franklin Antonio Hall.

Share This:

Stay in the Know

Keep up with all the latest from UC San Diego. Subscribe to the newsletter today.