New Biomaterial gets “Sticky” with Stem Cells

By:

- Catherine Hockmuth

Published Date

By:

- Catherine Hockmuth

Share This:

Article Content

Scanning electron microscope image of newly developed foam biomaterial with just the right amount of random stickiness so that stem cells can adhere and grow into mature tissue cells. Image Credit: Adam Engler, Department of Bioengineering, UC San Diego Jacobs School of Engineering.

Just like the bones that hold up your body, your cells have their own scaffolding that holds them up. This scaffolding, known as the extracellular matrix, or ECM, not only props up cells but also provides attachment sites, or “sticky spots,” to which cells can bind, just as bones hold muscles in place.

A new study by researchers at the University of California, San Diego and the University of Sheffield in the United Kingdom found these sticky spots are distributed randomly throughout the extracellular matrix in the body, an important discovery with implications for researchers trying to figure out how to grow stem cells in the lab in ways that most closely mimic biology. That’s because the synthetic materials scientists currently use to mimic ECM in the lab don’t have randomly distributed sticky spots, but instead are more uniformly sticky.

The study was published by Adam Engler, a bioengineering professor at UC San Diego Jacobs School of Engineering, and Giuseppe Battaglia, a professor of synthetic biology at the University of Sheffield in the Journal of the American Chemical Society (JACS). The group then mimicked this random stickiness in a foam biomaterial made out of polymers.

Battaglia and Engler explained that the foam uses two polymers, one that is sticky and one that is not, that separate from each other in solution. “It’s like what happens when you make balsamic vinaigrette and all the vinegar is randomly distributed in tiny bubbles throughout the oil,” said Engler. “We shook these two polymers up sufficiently to form randomly distributed nano-scopic patches of the sticky material amid the non-sticky material.”

At the appropriate ratio of sticky and non-sticky polymer, they found that it is possible to tune the size and distribution of the foam’s adhesive regions: having less sticky polymer in the foam made its adhesive patches smaller and more dispersed, just as with natural ECM.

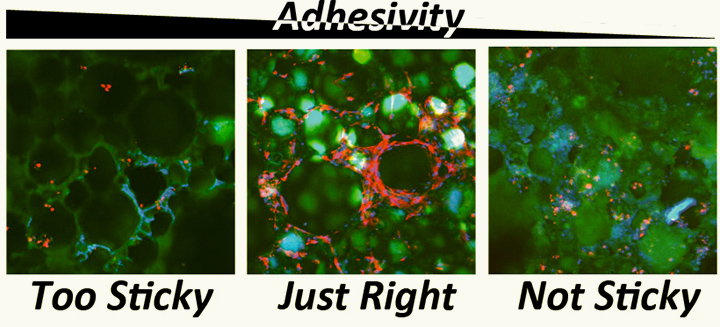

Immunofluorescent images shows the foam (green), stem cells (red) and stem cell nuclei (blue) with the middle image showing optimal foam stickiness for stem cell growth. Image Credit: Adam Engler, Department of Bioengineering, UC San Diego Jacobs School of Engineering.

What was surprising to the team was when they allowed stem cells to adhere to the foams, they found that random stickiness versus uniform stickiness was required for stem cells to properly adhere. They also found that this is likely necessary for stem cell development into mature tissue cells. As Battaglia explains, “In this sense, stem cells are like Goldilocks: the scaffold should not be too sticky or not sticky, it must be just right to maximize adhesion, and later, to cause stem cells to mature into tissue cells.”

The data published by Battaglia, Engler, and lead authors Priyalakshmi Viswanathan from the University of Sheffield and UC San Diego Bioengineering Ph.D. student Somyot Chirasatitsin should help better inform researchers of how to make their biomaterials appropriately sticky for stem cells to ‘feel’ their way around.

This work was supported by grants from the U.S. National Institutes of Health (DP02OD006460), Human Frontiers Science Program, and the Engineering and Physical Sciences Research Council in the United Kingdom.

Share This:

Stay in the Know

Keep up with all the latest from UC San Diego. Subscribe to the newsletter today.