Engineers Shake Tallest Steel-framed Building Ever Tested on an Earthquake Simulator

The primary goal of these tests: determining if height limits for cold-formed steel-framed buildings can be increased

Story by:

Published Date

Article Content

“Three, two, one!” The tallest steel-framed building ever tested on an earthquake simulator started moving slowly, swaying and twisting. The 10-story, 100-foot structure was experiencing simulations of real earthquakes, including the 6.9 magnitude, 1989 Loma Prieta temblor, as part of an effort to determine if height limits for buildings made of cold-formed steel could be increased.

The testing took place on an earthquake simulator, also known as a shake table, funded by the U.S. National Science Foundation, at the University of California San Diego. The shake table is one of the three largest in the world and the only one located outdoors. The outdoor location is especially crucial for tests like these, which push the boundaries in height limits for buildings. Indeed, the shake table is the only place in the world where buildings over 90 feet tall can be tested. Two years ago, researchers shook a 115 foot mass timber building on the UC San Diego shake table—the tallest building ever tested on a seismic simulator.

This year’s tests focus on a building made of cold-formed steel, or CFS, which is a lightweight, sustainable material that is not combustible and is made from 60% to 70% recycled metal. Currently, building codes limit this type of construction to 65 feet, or six stories. Researchers are asking whether the limit could be increased to 10 stories, or 100 feet, including in seismically active areas. Test results so far point to “yes.”

“The building performed very well,” said Tara Hutchinson, the project’s lead and a professor in the UC San Diego Department of Structural Engineering. “Despite 18 earthquake tests of increasing intensity—including three very large at and above what design engineers must consider in designing a building–the load-bearing structural system retained its integrity.”

But researchers were expecting some damage to the building’s non-structural components. The stairs, crucial to allowing building occupants to safely evacuate the building and designed to move with the building, were still functional.

“Within this building we installed nearly a thousand sensors to measure its response in terms of acceleration, displacement and local strains - we have an outstanding set of data to analyze and digest, and ultimately to help improve building codes and support the design communities’ desire to use this excellent material in the construction of taller, lightweight, more resilient buildings,” Hutchinson said.

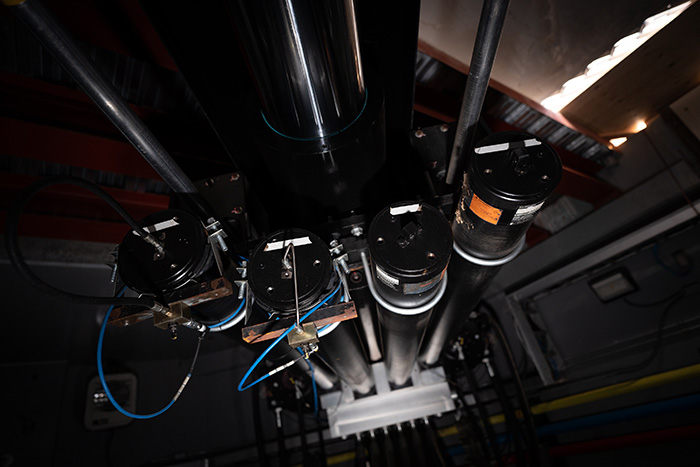

Since it is a lightweight material, cold-formed steel can be assembled in modular units, which can then in turn be assembled into a full building, like a giant version of Legos. This technique dramatically reduces the amount of construction time compared to constructing the building’s skeleton from scratch.

“CFS has a lot of really great features that are going to benefit resilient communities in the future,” Hutchinson said.

Photo: David Baillot/University of California San Diego

Important NSF-funded upgrade

The tests also pointed out the importance of a major upgrade to the shake table funded by the NSF. The $17 million project, completed in April 2022, gave the table the ability to move in six degrees of freedom. Before the upgrade, the table could only move in one direction, east to west. Now, it can also move up and down, north to south, and in roll, pitch and yaw motions. For example, in this series of tests, the team subjected the building to 1D, 2D, and 3D motions using the same earthquake record, by just turning off different degrees of freedom.

Recordings from past earthquakes show that the ground doesn’t shake in one direction—it moves back and forth, up and down, side to side and can even wobble, said Joel Conte, one of the lead researchers at the shake table and a professor in the UC San Diego Department of Structural Engineering. “Here we are able to simulate what we call near-real world earthquake conditions,” he said. During a test on June 23, researchers noticed a certain amount of twisting motion in the building’s movements–something that would not have happened when the table was only able to move in one direction.

“The motions that we saw today demonstrated why that table upgrade was critical to the science that we do here,” said Ben Schafer, CFS10 project co-lead and an engineering professor at Johns Hopkins University.

Photo: David Baillot/University of California San Diego

Upcoming fire tests

But the test series is not yet done. In addition to carefully reviewing the physical state of the building after the earthquake tests, the research team is preparing for a final phase of live-fire testing which takes place this month. These fire tests are being led by Professor Richard Emberley at Cal Poly-San Luis Obispo, and are aimed at understanding the temperature, smoke, and particulate spread throughout compartments in the building that were seismically damaged–a real scenario referred to as ‘fire-following earthquakes.’ These could be triggered due to gas or other hazardous substances serving as an ignition source. “CFS is non-combustible, unlike wood and some other building materials, an important beneficial characteristic if fires are a concern,” Hutchinson said.

Sponsors from academia and industry

In addition to the NSF, the CFS10 tests are sponsored by the U.S. Department of Housing and Urban Development, the California Seismic Safety Commission, the California Office of Emergency Services and the National Institute of Standards and Technology.

The tests also have garnered support from a significant number of industry organizations such as the American Iron and Steel Institute, the Steel Framing Industry Association and the American Institute of Steel Construction. Many companies have contributed substantially to the design and construction effort, including ClarkDietrich, Clark Construction, Standard Drywall Inc., Mid-Rise Modular, Bapko Metal, Grabber Fastening and others. View a complete list of sponsors.

Photo: Daniel Orren/University of California San Diego

The CFS10 tests are funded by NSF awards #1663569 and #1663348, as well as the aforementioned numerous sponsors and partners.

Share This:

Stay in the Know

Keep up with all the latest from UC San Diego. Subscribe to the newsletter today.